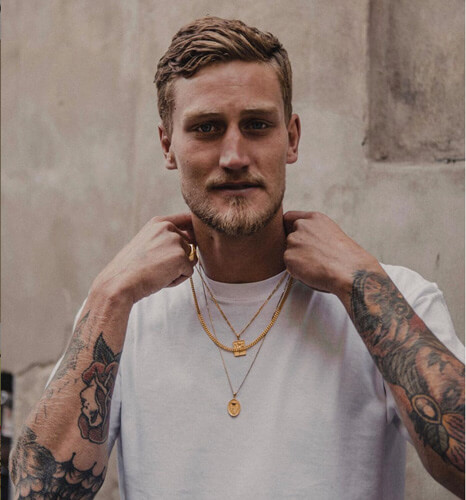

IX Studios - Løverne fik en Løvens Hule Loge Ring 🦁🏆 Skal vi hjælpe dig med en personlig indgravering på dine Frederik IX Studios smykker, som kongelige og adelige gjorde

Plaza Ure og Smykker - Den bæredygtige gave 🌿 Frederik IX skaber unisex smykker i 100% recycled guld og sølv. Hvem skal forkæles med et af de unikke smykker? 🌞 Du kan