![Amazon.co.jp: [Apple MFi Certified] iPhone USB Memory 128 GB iPhone Flash Drive [iPad USB Drive with Lightning Connector and USB Type C] iPhone USB External Memory Photo and Video Backup Stick, Supports Amazon.co.jp: [Apple MFi Certified] iPhone USB Memory 128 GB iPhone Flash Drive [iPad USB Drive with Lightning Connector and USB Type C] iPhone USB External Memory Photo and Video Backup Stick, Supports](https://m.media-amazon.com/images/I/61erhCMq0nL.jpg)

Amazon.co.jp: [Apple MFi Certified] iPhone USB Memory 128 GB iPhone Flash Drive [iPad USB Drive with Lightning Connector and USB Type C] iPhone USB External Memory Photo and Video Backup Stick, Supports

Amazon.com: SCICNCE 1TB Photo Stick iPhone Flash Drive, for iPhone USB Memory Stick Thumb Drives USB Stick External Storage Compatible with iPhone iPad Android PC (Dark Grey) : Electronics

Amazon.com: SCICNCE 1TB Photo Stick for iPhone Flash Drive, USB Memory Stick Thumb Drive External Storage Compatible with iPhone iPad Android Computer (Light Blue) : Electronics

![Amazon.co.jp: iPhone USB Flash Drive 256GB [Apple MFi Certified iOS 16 Compatible] iPhone Flash Drive 2 in 1 iPad Flash Memory Lightning + USB Type C Compatible iPhone Photo Video Backup Stick Amazon.co.jp: iPhone USB Flash Drive 256GB [Apple MFi Certified iOS 16 Compatible] iPhone Flash Drive 2 in 1 iPad Flash Memory Lightning + USB Type C Compatible iPhone Photo Video Backup Stick](https://m.media-amazon.com/images/I/9118PcYAzAL._SY350_PKmb-play-button-overlay_.jpg)

Amazon.co.jp: iPhone USB Flash Drive 256GB [Apple MFi Certified iOS 16 Compatible] iPhone Flash Drive 2 in 1 iPad Flash Memory Lightning + USB Type C Compatible iPhone Photo Video Backup Stick

Amazon.com: AMLLEN USB to iPhone Adapter,3.5mm Headphones/Earphones Jack Aux Audio Dongle Adapter,3 in 1 USB OTG Adapter with Charging for iPhone/iPad,Support USB Flash Drive,Keyboard,Microphone : Electronics

iPHONE OTG Adapter 3.0 Lightning to USB Port Apple Connector For ios, ipad - High SpeedUSB Female Support Connect USB Flash Drive, U Disk, for iPhone 12Pro 12 12Mini 11 Pro XS

Amazon.co.jp: Apple MFi Certified iPhone USB Memory, 128 GB, iPhone USB Flash Drive, Lightning for iPhone and iPad, USB Type C Connector, USB Memory, iPad Flash Memory, iPhone USB Memory, 360° Rotation,

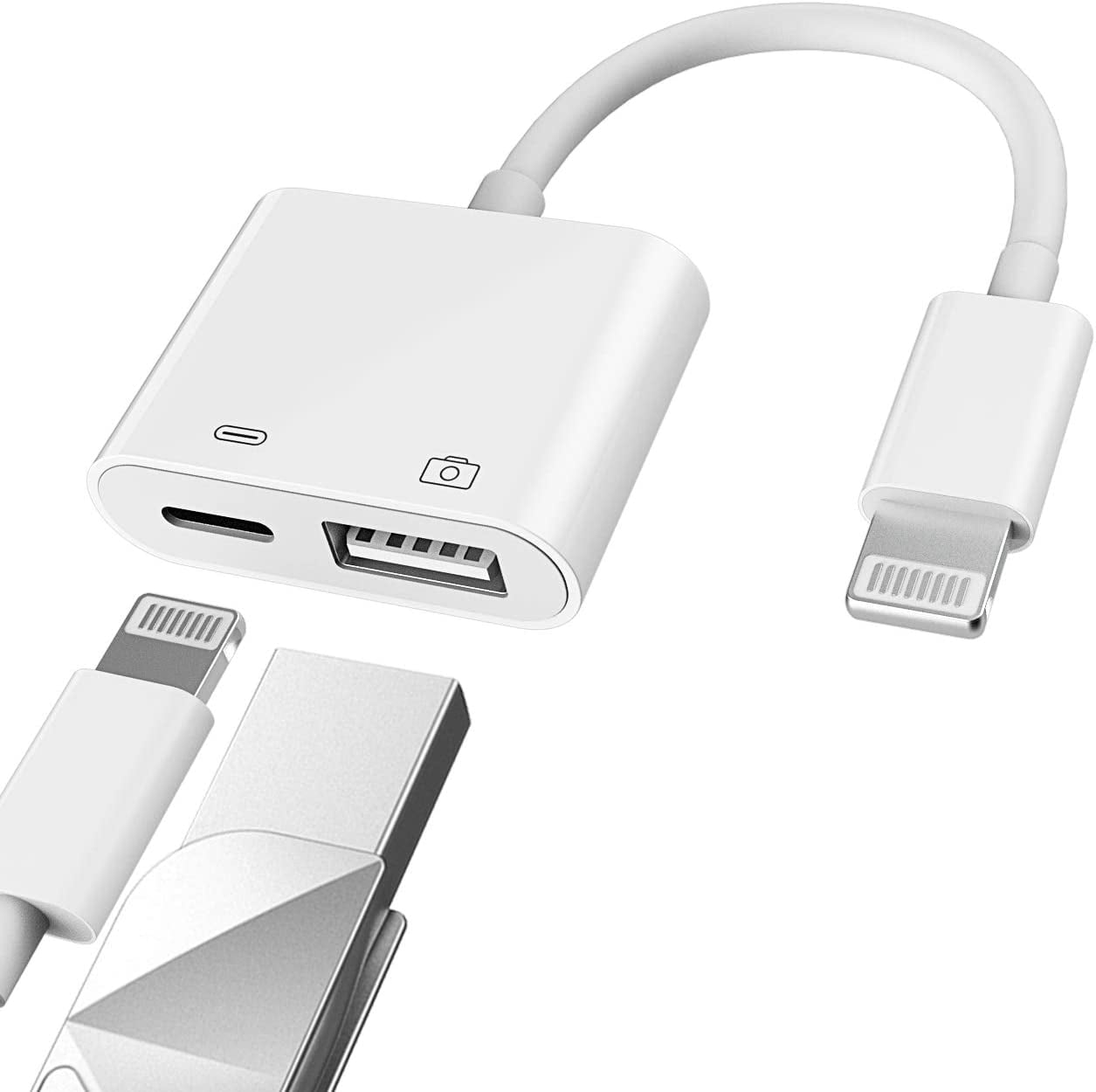

![Amazon.com: [Apple MFi Certified] Lightning to USB Camera Adapter for iPhone, USB OTG Adapter with Fast Charging Port Portable Compatible with iPhone/iPad/Card Reader/USB Flash Drive/Keyboard/Mouse Plug and Play : Cell Phones & Amazon.com: [Apple MFi Certified] Lightning to USB Camera Adapter for iPhone, USB OTG Adapter with Fast Charging Port Portable Compatible with iPhone/iPad/Card Reader/USB Flash Drive/Keyboard/Mouse Plug and Play : Cell Phones &](https://m.media-amazon.com/images/I/51HoDG6W6TL.jpg)

Amazon.com: [Apple MFi Certified] Lightning to USB Camera Adapter for iPhone, USB OTG Adapter with Fast Charging Port Portable Compatible with iPhone/iPad/Card Reader/USB Flash Drive/Keyboard/Mouse Plug and Play : Cell Phones &

USB Flash Drive for iPhone and iPad Photo Stick Memory Stick– USB 3.0 – External Storage Adapter Expansion for iOS PC Mac and Windows PC (128G, Grey) : Amazon.co.uk: Computers & Accessories

Amazon.com: Apple Lightning to USB Camera Adapter with Charging Port, USB 3.0 OTG Cable for iPhone/iPad to Connect Card Reader, USB Flash Drive, U Disk, Keyboard, Mouse, Hubs, MIDI, Plug & Play :

USB Camera Adapter, USB OTG Cable Adapter Compatible with iPhone/iPad, Support iOS 13 and Before, USB Female Supports Connect Card Reader, U Disk, Keyboard, USB Flash Drive,Plug & Play - Walmart.com

CROSSVOLT Metal USB OTG Adapter Compatible with i-OS 13 and Later, USB Female Support Connect USB Drive, for iPhone 12Pro 12 12Mini 11 Pro X, Gold, (IPHN OTG Gold) : Amazon.in: Electronics

Amazon.com: Bqbersyn USB Adapter for iPad/iPhone, Lightning to USB Female OTG Adapter Compatible with SD Card Reader/USB Flash Drive/Microphone/Hard Disk and MIDI,Plug & Play : Electronics

SanDisk iXpand Flash Drive Go 256GB USB 3.0 Type-A to Apple Lightning for iPhone & iPad Black / Silver SDIX60N-256G-AN6NE - Best Buy

Amazon.co.jp: Elecom MF-LGU3B128GBK USB Memory, 128 GB, iPhone/iPad Compatible, MFI Certified, Lightning Type-C Converter Adapter Included, Black : Computers

Lightning to USB Camera Adapter with Charging Port, Lightning Female USB OTG Cable Adapter for Select iPhone,iPad Models Support Connect Camera, Card Reader, USB Flash Drive, MIDI Keyboard - Walmart.com