festivalul Cenaclul Flacara, 43 articole de presa, (8 format A3 si 35 format A2) anii 80, de inramat (c25) – kolectionarul.ro

festivalul Cenaclul Flacara, 43 articole de presa, (8 format A3 si 35 format A2) anii 80, de inramat (c25) – kolectionarul.ro

festivalul Cenaclul Flacara, 43 articole de presa, (8 format A3 si 35 format A2) anii 80, de inramat (c25) – kolectionarul.ro

festivalul Cenaclul Flacara, 43 articole de presa, (8 format A3 si 35 format A2) anii 80, de inramat (c25) – kolectionarul.ro

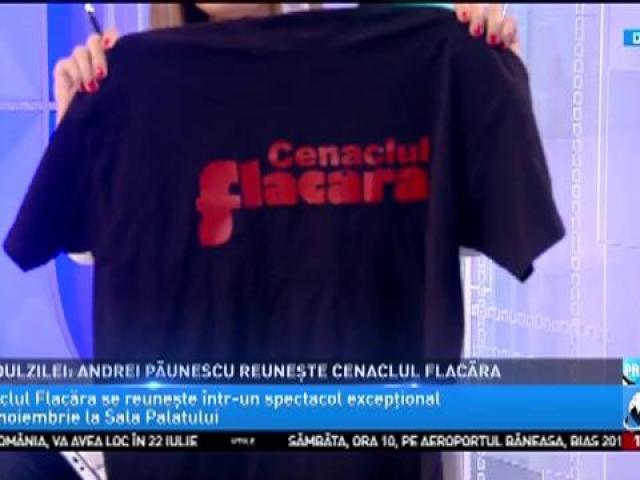

Acces Direct. Fiul lui Adrian Păunescu, acuzații dure la adresa lui Vasile Șeicaru. Andrei susține că i-a fost furată piesa / VIDEO | Spynews.ro

:format(jpeg):quality(80)/wp-content/uploads/2022/06/colaje-pentru-site-8-1.jpg)

Adevărul despre interzicerea Cenaclului Flacăra, la 37 ani de la tragedia de la Ploiești. "Adrian Păunescu avea pat pregătit la Jilava" - Fanatik.ro