Large Mouse Pad Xxl Diy Custom Doodle Monster Mousepad Desk Laptop Pad Cool Hypers Beast Mice Gamers Accessories Mouse Pad Wot - Mouse Pads - AliExpress

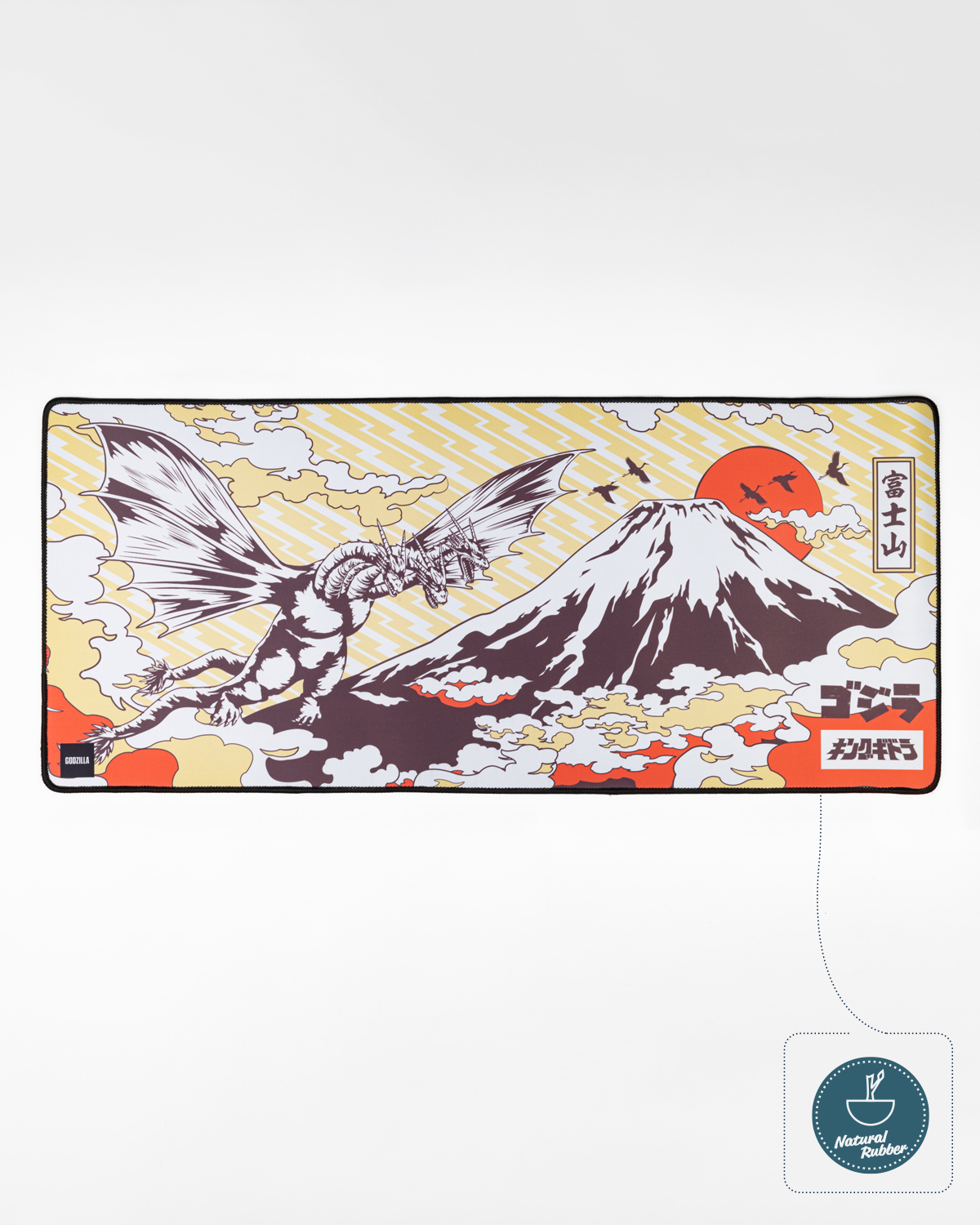

Monster Hunter Animationsfilm Gaming Rgb Musemåtte Stort Led Computer Musemåtte Rgb-baggrundsbelyst Mause Pad Til Pc Skrivebord Mus Mat Støtte Diy | Mus & Tastaturer < www.simonemoelle.dk