Vaping device e-cigarette electronic cigarette and liquid bottles isolated on white background. Vape device for alternative smoking. Vaping shop concept. Gadget for vaper. Vaping accessories. 7293784 Stock Photo at Vecteezy

Electronic cigarettes and bottles of yellow liquids. Vaping accessories on a white table. The concept of vaping. Smoking electronic cigarettes. Sale of Smoking accessories. Gadgets for Smoking. Stock Photo | Adobe Stock

Hot Sale Waterproof E-cigarette Case Pu Leather Case For Relx I Third Generation Cigarette Holder Smoking Accessories Case Pouch - Mobile Phone Cases & Covers - AliExpress

Vaping. Vape Smoke. Online Vape Shop. E-cig. Devices For The Vaper And Byloylki Liquid. Concept - Giving Up Nicotine. An Alternative To Smoking. Accessories For Vapes. Order An Electronic Cigarette. Stock Photo,

Vaping accessories on a white table. Smoking concept. Fashion for electronic cigarettes. E-cigarette and liquids on the table. VAPE shop. Stock Photo | Adobe Stock

SAMMY SMOKE SHOP - The Big Bar Duo Disposable E-Cigarette allows vapers to enjoy two different flavor options in one device. Users can change flavors via the switch located at the bottom.

San Francisco Vape Shop Near Me Smoke Shop Near Me Disposable Electronic Cigarette E Cigarette E-Cigarette Vape Cokii Max Disposable Vape Pod - China San Francisco Vape Shop Near Me, Cokii Vape

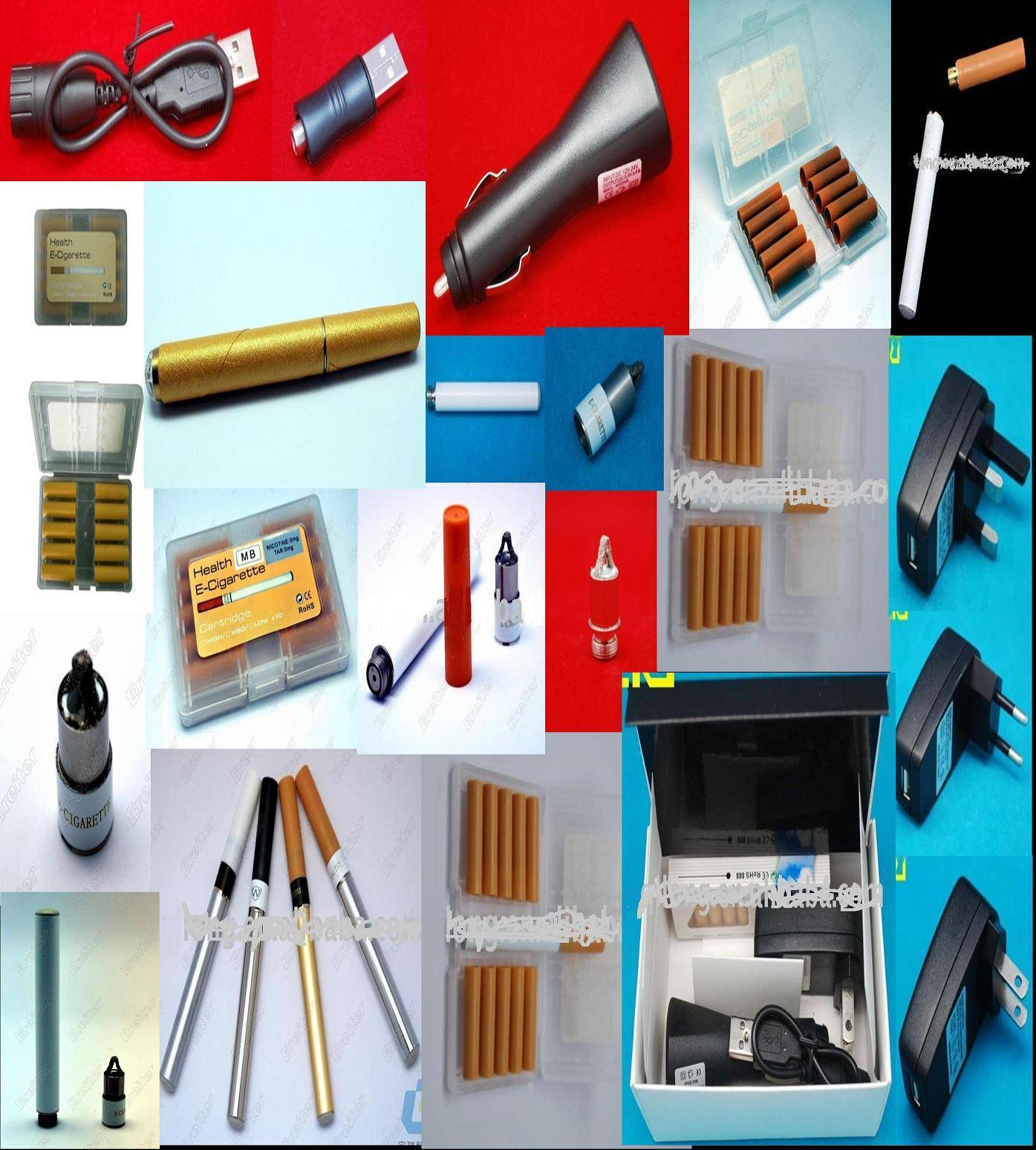

Wholesale E Cigarette Distributor Dry Herb Vaporizer Pen Smoking Accessories Rechargeable Vapes Battery Bounce Drum Box 6000puffs Vape Box - China Vape, E Cigarette | Made-in-China.com